A process where heated plastic sheets are shaped over a mold by applying vacuum pressure for forming.

Overview

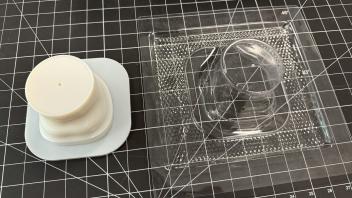

- Vacuum forming is a manufacturing process where a sheet of plastic is heated until pliable, then formed over a mold by applying a vacuum to pull the material tightly against the mold's surface.

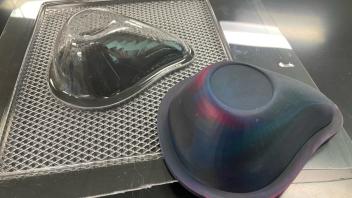

- This method is often used to create lightweight parts with generally uniform thickness, which can be either transparent or opaque.

- Vacuum forming is valued for its simplicity, cost-effectiveness, and ability to produce large or small batches with consistent quality

TEAM can assist with mold design, development, and manufacturing if needed.

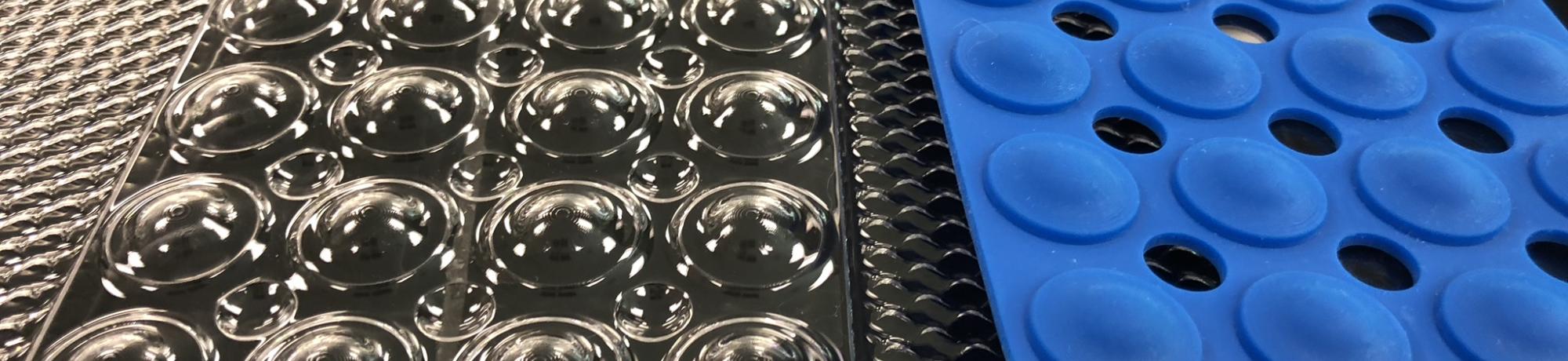

Photo(s)