Overview

- At the TEAM Lab, our dedication to excellence in 3D printing is backed by over a quarter-million combined print hours. This extensive experience means that our team possesses deep, hands-on knowledge of a wide range of 3D printing technologies, materials, and applications to ensure your needs are met.

- We feature an array of printing technologies to satisfy most applications. Below is an overview of our offerings.

3D printing technologies offer unique, affordable, and fast prototyping solutions. TEAM offers a variety of 3D printing technologies, each of which presents its own set of advantages and disadvantages. Please use the descriptions, combined with the printer-comparison guide found below when selecting a technology. Please also feel free to contact us for further clarification.

General Comparison of Available Technologies:

| Printing Technology | Material Strength | Accuracy | Geometric Freedom | Relative Cost |

|---|---|---|---|---|

| FDM - Fused Deposition Modeling | Very Good | Fair to Good* | Fair | $ |

| Reinforced FDM | Excellent | Very Good | Good | $$-$$$$$* |

| SLA/MSLA - Stereolithography | Good to Very Good* | Very Good to Excellent** | Very Good | $$-$$$* |

| Polyjet | Poor | Excellent | Excellent | $$$-$$$$* |

| DLP - Digital Light Processing for Microfluidics Printing | Good | Excellent | Good | $$$$ |

| * Function of material selection | ** Function of geometry | * Function of material selection |

Rapid Material Selection Matrix

Below are common considerations in material selection shown against our available printing technologies.

| Thermoplastic - FDM & Reinforced FDM | Resin - SLA | Resin - Polyjet | Resin - DLP (For uFluidics) | |

| Economical Materials | Yes | No | No | No |

| Translucent Option | Yes | Yes | Yes | Yes |

| Clear Option | No | Yes | Yes | Yes |

| Chemical Resistance | Yes | Yes | No | No |

| Biocompatible Option | No | Yes | Yes | No |

| Autoclave Compatibility | No | Yes | No | No |

| High Temperature Stability Option | No | Yes | No | No |

| Liquid Tight/Non-Porous | No | Yes | Yes | Yes |

| High Resolution | No | Yes | Yes | Yes |

Thermoplastic Printing

FDM – Fused Deposition Modeling

FDM 3D Printing is a technique whereby a layered object is deposited as a semi-continuous thermoplastic filament extruded from a hot-nozzle. The deposition process this machine uses can be envisioned as a precisely controlled hot-glue-gun. This is the most common 3D printing technique on the market, as it is capable of making durable and economical parts. However, its ability to achieve complex geometry is somewhat limited in comparison to other technologies, and its printing resolution is comparatively course (with layer thicknesses generally at or around 200 microns, and minimum feature size of roughly 1mm).

Relative Performance

Strengths:

- Economical

- Good material variety (limited to thermoplastics)

- Multi-Material Printing

- (Simple) Printed Assemblies

Weaknesses:

- Surface finish can be perceived as rough compared to other technologies

- Lacks fine-feature resolution

- Less geometric freedom compared to other technologies

- Hollow and porous parts (typically not compatible with applications that require containment of liquids)

- Opaque materials only

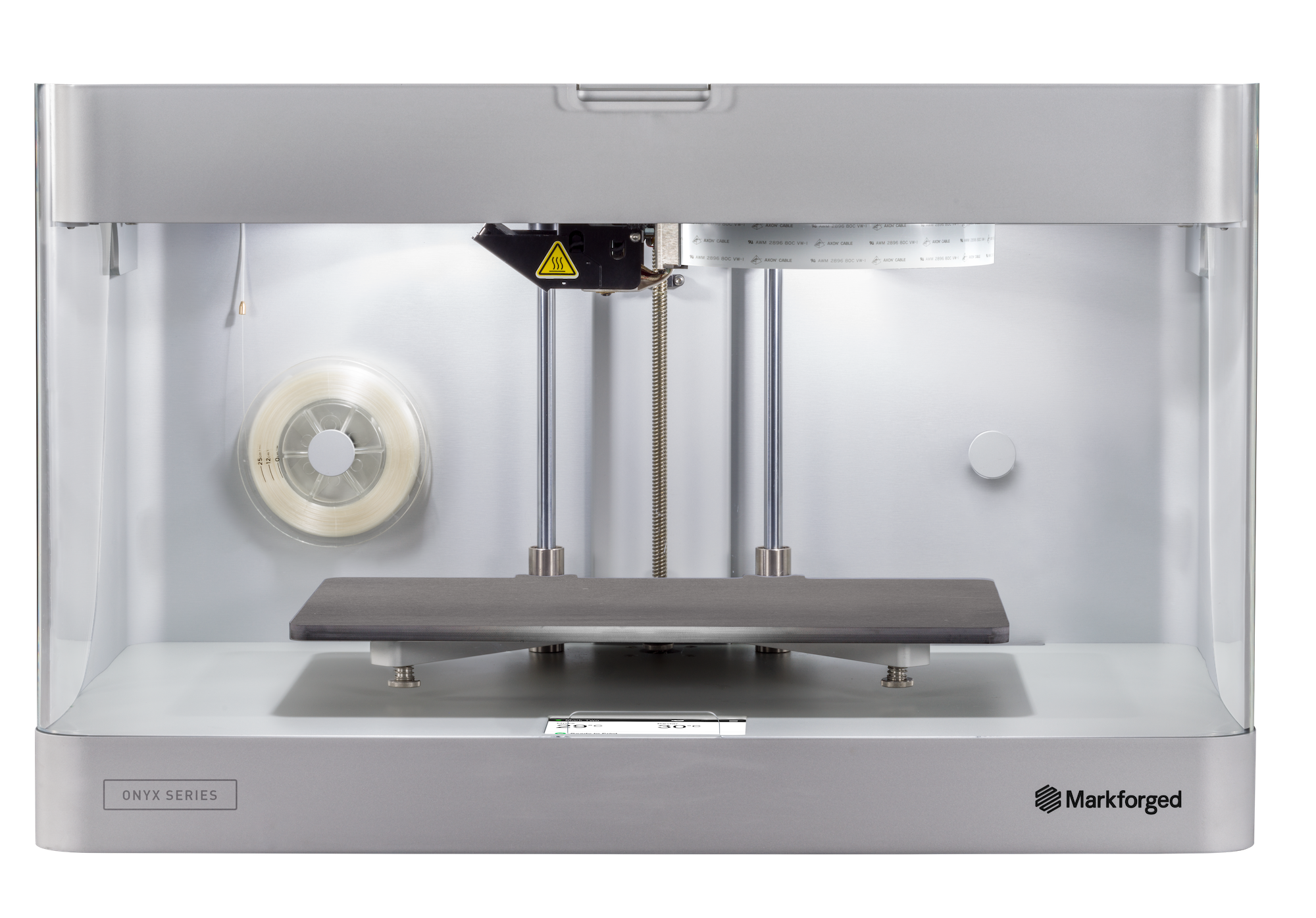

Reinforced FDM

Reinforced FDM 3D Printing is an extension of standard FDM printing. The primary differences being:

- The primary build material is (always) a composite consisting of chopped carbon fibers embedded in bulk Nylon (“Onyx”) in place of PLA, ABS, etc.

- (Optional) Continuous bands of fiber filament (carbon fiber, fiberglass, or Kevlar) embedded in the above “bulk” printer material, applied in the Z-plane.

Relative Performance

Strengths:

- Extreme part strength potential

Weaknesses:

- Very limited material options

- Lacks fine-feature resolution

- Less geometric freedom

- Hollow and porous parts (typically not compatible with applications that require containment of liquids)

Resin Printing

SLA/MSLA – Stereolithography

SLA (and MSLA) 3D Printing is a technique whereby an object is etched into UV-curing liquid resin via laser (or UV display) in a series of stacked layers. This printing technology is best where strength and accuracy are both important considerations, or where geometry may be too complex to achieve via FDM printing. Prints derived from this platform are also non-porous and can therefore retain liquid (a common design consideration). Further, many SLA/MSLA resins afford high-temperature resistance, sterilizability, and biocompatibility.

Relative Performance

Strengths:

- High resolution and detail

- Smooth surface finish

- Translucent (clear with polishing) material options*

- Wide range of material options

- Fully solid parts

- Flexible material options

- Biocompatibility*

- Sterilizable*

Weaknesses:

- Higher material costs

- Greater processing costs

- Largely proprietary (and finite) set of available materials

- Greater environmental impact

More SLA printing service details

*resin dependent

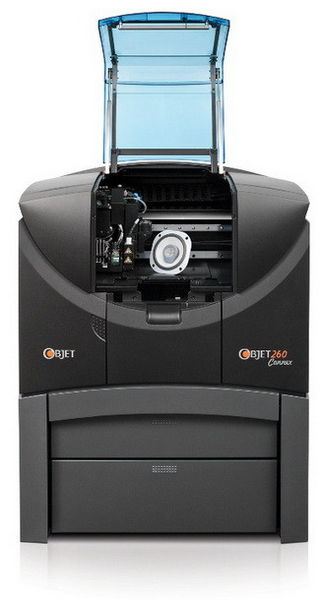

Polyjet – Jetted Photopolymer

Polyjet printing is a 3d deposition process that shares many similarities to traditional, 2D inkjet printing. However, instead of jetting droplets of ink onto paper, Polyjet printing deposits a UV curing liquid resin onto a build platform which is solidified immediately following the jetting process. This process is looped in successive layers. Upon completion of the print, a gel-like temporary support structure is removed via high-pressure water.

As the layer size is typically around 22 microns, this printing technology is capable of extreme precision in comparison to FDM printing, and is slightly better than SLA printing. However, the cost for this level of precision is that materials are significantly weaker, and often more expensive.

Coupling this level of precision with a dedicated support structure permits the development of “printed assemblies,” whereby multiple pieces are held in suspension from one another with support structure, printed as one part, and separated after cleaning to reveal a functional part.

Relative Performance

Strengths:

- High resolution and detail

- Fully solid parts

- Multi-Material Printing

- Printed Assemblies

- Translucent/Clear (with polishing) material options

- Flexible material options

Weaknesses:

- Higher material costs

- Greater processing costs

- Very few material options

- Proprietary materials

DLP - Digital Light Processing for Microfluidics

DLP 3D Printing is a technique where an object is formed by selectively curing layers of liquid resin with a digital light projector. Unlike SLA, which uses a laser, DLP uses a digital light source to cure entire layers simultaneously, leading to faster print times. This technology is known for its high resolution, capable of producing fine details with smooth surface finishes, making it ideal for intricate designs and detailed prototypes. However, DLP is generally less suited for parts requiring high strength or large, solid volumes due to material limitations.

Our DLP Printing technologies are purpose-build for microfluidic applications; we are capable of printing clear, single-use chips, or molds for use in conjunction with PDMS.

Relative Performance

Strengths:

- High resolution and detail

- Smooth surface finish

- Optically clear prints

- Fully solid parts

- Capable of printing small-diameter channels with high aspect ratios

- Purpose-built for micro fluidics work

Weaknesses:

- Higher material costs

- Greater processing costs

- Only two material options

How to Leverage These Technologies

The input to each of these machines would be a mm-scale STL file, exported from your CAD (Computer Aided Design) package of choice. Submit these files (with your original parametric model files, if possible) in a service request for review.

In instances where multi-material parts are desired, please ensure multiple files (one for each material type) are provided in a shared coordinate system. Please work with a TEAM staff member to alleviate any confusion on this topic (we're always happy to help!).

Get Started

- Heard enough? Get started with a service request! Your request need-not be perfect, we can always revise it as we go. Just provide us with as much detail as is necessary.

- Feeling overwhelmed with the options? We don't blame you! We do a lot! Feel free to email us to set up a consultation. We're happy to chat via zoom, or in person (where we can review samples).